|

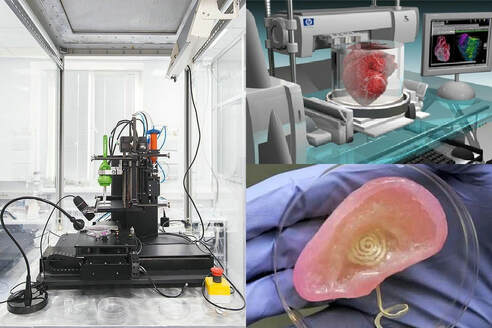

Written by: Angela Yeung ‘24 Edited by: Surya Khatri ‘23 & Owen Wogmon ‘24 Shortly after turning five years old, Mia Gonzalez—with her sweet smile and large expressive eyes—faced a grim diagnosis: double aortic arch, a deadly congenital heart deformation that restricts airflow, causing phases of choking and shortness of breath [1]. To prepare for the surgery, Mia’s surgical team made the unprecedented decision to center their operation around a 3D-printed model of her heart. This plan involved imaging Mia’s heart with CT imaging, uploading that data into the Stratasys Objet500 Connex3 Multi-Material 3D Printer, then producing a life-size model of the heart down to the smallest detail, including her “very complex aortic arch vessels.” [1] Through this, the surgical team was not only able to drastically reduce operation time but also achieve the highest level of preparation—they were able to fully visualize the path of surgery using the 3D printed model. Mia quickly recovered and returned to a happy and healthy life two months post-operation. Compared to traditional 2D home and office printers, which haven’t had many updates in the past few years, 3D printing is already at the forefront of medical innovation . Also known as additive manufacturing or rapid prototyping, 3D printing was invented in the 1980s by engineer and physicist Chuck Hull [2]. The core concept of the technology is the deposition of material, one layer at a time. This is analogous to the printing method of the more commonly seen inkjet printer—while dots of ink are added onto paper one at a time, eventually forming text or image, 3D printers print objects through the collection of information from digital files and the subsequent addition of material in space where it is needed. 3D printing holds the potential to not only reduce material costs by up to 90%, but to also preserve over 50% of energy (as opposed to many conventional manufacturing processes, which use subtractive manufacturing) [3]. Subtractive manufacturing is a method in which excess materials are dissected away to produce the final product. This proves to be severely inefficient, wasting up to 30 lbs of total material for every 1 lb of useful material [4]. On the other hand, there are infinite possibilities for innovation when it comes to additive manufacturing: besides the sustainability factor, the implementation of compatible new materials has allowed 3D printing to become increasingly advantageous, for the medical industry in particular. Bioprinting is now one of the most common techniques used in the medical industry. Though standard 3D printing materials are polylactic acid (PLA) filament and acrylonitrile butadiene styrene (ABS) filament, because both are plastic, they are not compatible with the human body. (However, these materials are used for 3D-printed models to guide surgeons through their operating plan.) Therefore, bioprinters use bioink, a synthetic substance which is squeezed through a computer-guided pipette to overlap living cells on top of each other, the final product being artificial living tissue [5]. Also known as organoids, these tissues allow scientists to test-run drugs in development by seeing how they interact with biosystems [6], essentially paving the path for advancements in personalized medicine, especially when it comes to organ transplantation. 3D printing also allows scientists to take it a step further by allowing them to produce a realistically-sized organ instead of a scaled-down model (organoid). Bioprinted organs greatly reduce the possibility of encountering complications due to bio-incompatibility or long waits for donor organs. The procedure for bioprinting organs is essentially the same as the creation of organoids: cells are harvested from the recipient and used to create an exact replica of the desired organ [5]. Besides the heart, bioprinters are able to construct other anatomical structures, such as skin and bones. The conventional treatment for complex bone fractures is bone grafting, a technique in which the missing bone is repaired by harvesting replacement bones from other sites of the body. This, however, comes with several limitations, such as pain around the donor site, infection, and blood loss [7]. Furthermore, bone grafting may lead to compromised mechanical integrity of the healed bone in the future. Bioprinted bones avoid these complications by not only using a durable and regenerative material but also by having the ability to slowly fuse with the patients’ other bones over time [5]. In bioprinting, the cells used are ideally collected from the patient, then refined into the desired bioink; adult stem cells are used if collection from the patient proves to be infeasible. The final organic product is produced through a molding process: cells are bonded to each other with the use of a dissolvable gel as a frame. Over the past decade, 3D printing has gone from being a niche industry manufacturing technique to skyrocketing in popularity. Overall, 3D printing in the medical field is predicted to soar to $3.5B in value by 2025, from a previous value of $710m in 2016 [5]. Outside medicine, though, 3D printing has revolutionized many industries to date, one of the most notable being the consumer goods industry. It has observed accelerated development cycles and greater design flexibility—with 3D printing, the iterative design process (the continuous improvement of a product through the creation and modification of prototypes) could be shortened from weeks to days; this is attributed to the increasing ease of manufacturing prototypes [8]. Similar to the customizations that are now possible in the medicine, tailored products in the consumer goods industry are now much more straightforward to make; on the contrary, conventional subtractive manufacturing would require costly design modifications based on individual wants. The newfound boom in popularity has contributed to the rise of 3D printing as a hobby. This could be attributed to the accessibility of this novel technology—today, anyone can visit open-source websites such as Thingiverse, download a file, send it to their 3D printer, and print out the object of their choosing. The economic feasibility of purchasing 3D printers also contributes to the rapid rise in popularity (some 3D-printers sell at only $100). Moreover, free complementary software such as the SCENECT plays a role in making 3D printing accessible to all. Though 3D-scanning software has existed for quite some time, the SCENECT app is completely free of cost compared to the thousands of dollars that other scanning technologies may require. This allows anyone interested to delve into the world of 3D printing; because of this rapidly decreasing cost of production, 3D-printers make it possible for designers and hobbyists to make the most of their creativity. There are immeasurable opportunities on the horizon when it comes to 3D printing; there is potential for revolutionizing every industry, from life-saving medicine to everyday consumer goods. Some predictions for 3D printing in the future include the integration of machine learning and additive manufacturing, allowing the 3D printing process to be analyzed and modified, avoiding defects in the manufacturing cycle and making it more efficient than ever. As of right now, 3D printing is already spearheading the development of efficient production; even more than that, it is saving the lives of patients like Mia Gonzalez and those who are on transplant waitlists. From being hailed as one of the most ingenious technological breakthroughs of the modern world to becoming easily accessible to the public, 3D printers have become vessels of creativity and innovation for researchers, surgeons, and hobbyists alike. Works Cited:

4 Comments

Thanks for helping me understand that bioprinting is used in the medical industry to create body parts compatible with patients. I guess this just shows how 3D printing has really made an impact on the world. It is good to know that people with disabilities can have a better life once they have missing body parts made specifically for them.

Reply

1/17/2023 07:02:51 am

Excellent article! Thank you for your excellent post, and I look forward to the next one. If you're seeking for discount codes and offers, go to couponplusdeals.com.

Reply

2/28/2023 02:17:39 pm

It stood out to me when you mentioned that there are immeasurable opportunities on the horizon when it comes to 3D printing. If you are wanting your business to implement 3D printing, I would think that it would be a good idea to find an experienced manufacturing company that you can partner with. Partnering with a 3D printing company would make it so that you don't have to spend a lot of time learning how to use this technology.

Reply

Leave a Reply. |